General Info

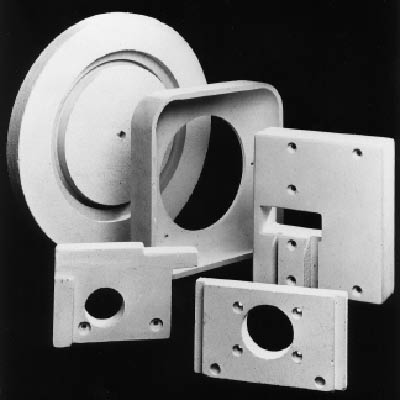

ZIRCAR Refractory Composites Inc., provides a variety of non-asbestos calcium silicate structural insulations that combine high strength and excellent thermal insulating characteristics for use in a variety of heat processing, fire protection and electrical resistance applications. The unique calcium silicate structure provides excellent thermal shock resistance as evidenced in its typical use as a direct contact board for non-ferrous metals and in fire training burn rooms. They are fire resistant to temperatures approaching 1100°C(2012°F). They also exhibit low thermal conductivities that remain relatively constant over a broad range of operating temperatures.

ZIRCAL-18 Refractory Board is a high temperature calcium silicate block insulation with excellent mechanical properties and stability up to 1100°C(2000°F). Its high thermal insulating value makes it ideal for many fireproofing and heat processing equipment applications. ZIRCAL-18 is designed to serve as a backup insulation for any refractory construction, such as insulating fire brick, dense refractory brick, castable, gunning mix, plastic refractory or ceramic fiber. ZIRCAL-18’s high refractoriness and strength help prevent catastrophic failure of the refractory system. Often the hot face refractory can crack in service allowing the backup insulation to be exposed to elevated temperatures. ZIRCAL- 18 makes continued use of the operation possible, allowing for orderly shutdown and maintenance. In the aluminum industry, ZIRCAL-18 is ideally suited as an electrolytic cell insulation. Its combination of strength, thermal conductivity, stability and handleability makes it ideal for reduction cell applications. In the petrochemical industry, ZIRCAL-18 is ideally suited as a backup insulation in heaters and furnaces, and in applications requiring high strength such as insulated pipe.

ZIRCAL-45 Refractory Board is a self-supporting, high strength, rigid refractory product fabricated from calcium silicate, inert fillers and reinforcing agents. Its high structural strength combined with high thermal insulating value make it ideal for many fireproofing and heat processing equipment applications up to 650°C(1202⁰F). ZIRCAL-45 is highly damage resistant, non-corroding, and extremely water- resistant. ZIRCAL-45 in full size 4’ x 8’ panels offer major economic advantages in the construction of ovens, dryers, and other insulated housings for the retention and control of heat. ZIRCAL-45 can be readily fabricated into various sizes and shapes for heat baffles and all types of insulating parts. It is used in fire safety applications such as fire stops, fire walls, cable trays and fire doors, and provides an ideal, incombustible base for melamine veneers. ZIRCAL-45 panels have flame spread and smoke developed ratings of 0 & 0, and are not damaged by inflammable charges that are subject to occasional flaming. ZIRCAL-45 is not affected by moisture or high humidity, and will not rust or corrode. The panels will not disintegrate even after prolonged immersion in water. While panels can be painted if desired, preservative treatments are not required for interior applications. ZIRCAL-45 is hygroscopic and electrical resistance is reduced when it absorbs moisture. For electrical applications, ZIRCAL-45 components should be thoroughly dried or moisture proofed before use.

ZIRCAL-60 is an incombustible, self- supporting board that combines high insulating values, fire safety, and exceptionally high compressive strength in a variety of fire protection and heat processing applications. Damage-resistant ZIRCAL-60 insulation is a non-asbestos material formed from calcium silicate with inert fillers and reinforcing agents. It combines structural strength and thermal insulation properties in a single material. Because of its thermal insulating values and high compressive strength, ZIRCAL-60 structural insulation is especially well suited to withstand both the temperatures and pressures associated with platen press operations. It also provides durable, low maintenance insulation for large diameter pipe support systems in the power generation and process industries. It provides an ideal backup insulation in rotary kilns in lime and cement plants, and steel ladles, torpedo cars and tundishes in steel plants. In these applications, ZIRCAL-60 has withstood estimated hot face temperatures of 1700-1800°F (926-982⁰C), and has performed well where less compressive-resistant boards have failed.

In ceramics and foundry applications, ZIRCAL-60 insulation can be used as a pallet to support special refractory shapes and foundry cores during oven drying. In addition, it provides an effective alternative for many of the industrial applications which previously used non-asbestos flat sheets. The maximum service temperature of ZIRCAL-60 is dependent upon the application, and application parameters vary greatly in size, thickness, temperature, heat flow equilibrium and construction — carefully review the enclosed data and also consult your sales representative/distributor for application recommendations.

ZIRCAL-95 Refractory Board is produced from a combination of natural organic fibers and inert reinforcing fillers in a high-density calcium silicate hydrate matrix. Designed as a substitute for asbestos cement boards, ZIRCAL-95 is useful as structural and electrical insulation in applications with temperatures to 1000°C(1832°F). ZIRCAL-95’s surface is sanded smooth. It has a uniform consistency making it a useful source for custom machined insulating parts. ZIRCAL-95 combines low thermal conductivity and good dielectric properties with high mechanical strength. It is hygroscopic and contains a small amount of moisture. For certain high temperature electrical insulation applications, ZIRCAL-95 should be thoroughly dried for 24 hours at 100⁰C-150⁰C. It is ideal for use as press platen insulation, foundry core and blow plates, induction furnace casing, electrical resistance insulation, hot glass handling, as well as many others.

ZIRCAL-A is a strong, machinable, non-asbestos and inorganic board insulation ideal for conveying, containing, handling and forming molten aluminum and other non- ferrous metals. ZIRCAL-A can be used in aluminum contact applications up to approximately 816°C (1500°F). Made of fibers, micro silica and a hydro thermally produced inorganic binder, and are ideal materials for conveying and controlling the flow of aluminum. They are manufactured for greater life and improved machining characteristics. In addition, high heat treatment removes excess water, and minimizes shrinkage that would normally occur in service. This unique material has many outstanding advantages. Most Non-Ferrous metals do not adhere to it, even when they cool and solidify, so skull can be easily removed. It will require no foundry facing wash, and does not lead to contamination of the metals. Molten metals are conveyed with less heat loss, so stay at a more uniform temperature, and therefore can be handled at a lower temperature. Because they have a low heat capacity, preheating isn’t required. They are crack- and shock-resistant, and offer cost efficiency through a long service life.

ZIRCAL-A was developed as a replacement for asbestos containing materials, as well as N-14 (L-14) and B-3 (M1) boards. Its improved characteristics include higher strength, which equates to better machinability, and greater toughness for more resistance to physical abuse. ZIRCAL-A also has significantly reduced shrinkage at molten aluminum temperatures. It is used for basic parts such as floats, spouts, stopper pins, distribution boxes, dams, baffles, filter boxes, launders, troughs, head boxes, plus more sophisticated parts such as transition plates, hot top rings (especially large diameter) and as the working lining in low energy aluminum die cast holding furnaces.

Properties

| TYPE | ZIRCAL-18 | ZIRCAL-45 | ZIRCAL-60 | ZIRCAL-95 | ZIRCAL-A |

| Nominal composition, wt% | |||||

| CaSiO3 | 93 | 95 | – | 96 | – |

| Other oxides | 1.5 | <5 | – | <4 | – |

| Moisture | – | 3 | – | 1 | – |

| Loss on ignition | 5.5 | – | – | – | – |

| Density, g/cc (pcf) | 0.28(17.5) | 0.76(46) | 0.96(60) | 1.4(85) | 1.04(65) |

| Maximum use temp.*, °C(°F) | 1100(2012) | 650(1202) | 1000(1832) | 816(1500) | |

| MOR**, MPa(psi) | |||||

| MOR @ room temp. | 1.1(160) | 5.6(800) | 9.6(1400) | 18(2600) | 9.6(1400) |

| Compressive strength**, MPa(psi) | |||||

| 5% deformation | 1.4(203) | 70(1000) | 21(3050) | 45(6400) | 17(2400) |

| 12 hrs. at 650°C(1202°F) | 0.0 | 0.4 | 0.16 | 0.13 | 0.1 |

| 12 hrs. at 1050°C(1922°F) | 1.0 | – | – | 0.5 | – |

| Thermal Conductivity**, | |||||

| W/mK(BTU/hr ft2 oF/in.) | |||||

| 200°C(392°F) | 0.07(0.49) | 0.12(0.81) | – | 0.31(2.13) | – |

| 400°C(752°F) | 0.09(0.62) | 0.12(0.81) | 0.16(1.13) | 0.27(1.80) | 0.28(2) |

| 600°C(1112°F) | 0.10(0.69) | 0.12(0.81) | 0.17(1.15) | 0.29(2.01) | 0.28(1.92) |

| Coefficient of thermal | |||||

| expansion, K-1(°F-1) | 5.5 x 10-6 | 5.5 x 10-6 | – | 5.5 x 10-6 | – |

| 20°C – 700°C (68°F – 1292°F)

Volume Resistivity, ohm-cm |

(3.1 x 10-6) | (3.1 x 10-6) | – | (3.1 x 10-6) | – |

| ASTM D-257 | – | 9.8 x 107 | – | 4.52 x 1012 | – |

| Arc Resistance, sec. | |||||

| ASTM D-495 | – | – | – | 314 | – |

| Dielectric Strength, volts/mil | |||||

| ASTM D-495 | – | 45 | 46 | 61 | – |

| Screw holding strength | |||||

| @ 7/8″ penetration, kg(lbs) | – | 91(200) | 227(500) | 397(875) | 109(240) |

* Maximum use temperature is dependent on variables such as stresses, both thermal and mechanical, and the chemical environment that the material experiences.

** Properties expressed parallel to thickness.

‡ Properties expressed perpendicular to thickness.

Composition

-

Thermal shock resistance and stability – will withstand continuous heat up to its full temperature limit.

-

A consistently low thermal conductivity means high energy savings.

-

High structural strength at elevated temperatures – retains full integrity across a broad range of temperatures.

-

Incombustible – ideal for personnel protection, cable trays, fire doors, and marine applications.

-

Easily machined to tight tolerances with conventional tooling.

Instructions

APPLICATION

Uses include insulation for Annealing furnaces, Blast furnace stoves, Bustle pipes, Car tops, Forge furnaces, Glass lehrs, Heat treating, Hi-temp mains and flues, Industrial boilers, Kiln cars, Kilns, Laboratory furnaces, Marine boilers, Ovens, Pot furnaces, Petrochem heaters, Pipe supports, Regenerators, Reheat furnaces, Reverberatory furnaces, Roasters, Soaking pits, and Utility boilers.

FABRICATION INFORMATION

Zircal-95 has unique machining characteristics. It is easily cut with hand held woodworking tools using slow cutting action. Operator will notice the rate of material removal decreases as increased force and tool speed is applied. When sawing by hand, a slow steady motion works best. Zircal-95 has been successfully machined using power equipment with the following parameters:

- Sawing: Diamond wheel, approximately 250 mm diameter with 12 mm long teeth spaced 25 mm apart, 1800 RPM.

- Milling: Double edge carbide end mill, speed approximately 4000 RPM , feed rate – 4 m/min.

- Turning: Carbide tipped tools used on 50 mm diameter part at 1200 RPM, feed rate – 4 m/min.

Download the ZIRCAL Board PDF File

SDS (in PDF format)

Other Information

AVAILABILITY

Please call, fax or e-mail for pricing and availability.

| Item # | Description |

| SS60 | ZIRCAL-18, 24″ X 36″ X 1″ |

| SS61 | ZIRCAL-18, 24″ X 36″ X 1.5″ |

| SS62 | ZIRCAL-18, 24″ X 36″ X 2″ |

| SS63 | ZIRCAL-18, 24″ X 36″ X 2.5″ |

| SS64 | ZIRCAL-18, 24″ X 36″ X 3″ |

| SS65 | ZIRCAL-18, 24″ X 36″ X 3.5″ |

| SS66 | ZIRCAL-18, 24″ X 36″ X 4″ |

| SS70 | ZIRCAL-18, 48″ x 36″ x 1″ |

| SS71 | ZIRCAL-18, 48″ X 36″ X 1.5″ |

| SS72 | ZIRCAL-18, 48″ X 36″ X 2″ |

| SS73 | ZIRCAL-18, 48″ X 36″ X 2.5″ |

| SS74 | ZIRCAL-18, 48″ X 36″ X 3″ |

| SS75 | ZIRCAL-18, 48″ X 36″ X 3.5″ |

| SS76 | ZIRCAL-18, 48″ X 36″ X 4″ |

| SS30 | ZIRCAL-45, 48″ X 96″ X 1/2″ |

| SS31 | ZIRCAL-45, 48″ X 96″ X 3/4″ |

| SS32 | ZIRCAL-45, 48″ X 96″ X 1″ |

| SS33 | ZIRCAL-45, 48″ X 96″ X 1 1/4″ |

| SS34 | ZIRCAL-45, 48″ X 96″ X 1 1/2″ |

| SS35 | ZIRCAL-45, 48″ X 96″ X 2″ |

| SS40 | ZIRCAL-45, 48″ X 48″ X 1/2″ |

| SS41 | ZIRCAL-45, 48″ X 48″ X 3/4″ |

| SS42 | ZIRCAL-45, 48″ X 48″ X 1″ |

| SS42 | ZIRCAL-45, 48″ X 48″ X 1″ |

| SS43 | ZIRCAL-45, 48″ X 48″ X 1 1/4″ |

| SS44 | ZIRCAL-45, 48″ X 48″ X 1 1/2″ |

| SS45 | ZIRCAL-45, 48″ X 48″ X 2″ |

| SS46 | ZIRCAL-45, 48″ x 48″ x 3″ |

| SS50 | ZIRCAL-45, 24″ X 48″ X 1/2″ |

| SS51 | ZIRCAL-45, 24″ X 48″ X 3/4″ |

| SS52 | ZIRCAL-45, 24″ X 48″ X 1″ |

| SS53 | ZIRCAL-45, 24″ X 48″ X 1 1/4″ |

| SS54 | ZIRCAL-45, 24″ X 48″ X 1 1/2″ |

| SS55 | ZIRCAL-45, 24″ X 48″ X 2″ |

| SS56 | ZIRCAL-45, 24″ x 48″ x 3″ |

| SX01 | ZIRCAL-60, 48″ X 96″ X 1/2″ |

| SX02 | ZIRCAL-60, 48″ X 96″ X 3/4″ |

| SX04 | ZIRCAL-60, 48″ X 96″ X 1 1/2″ |

| SX05 | ZIRCAL-60, 48″ X 96″ X 2″ |

| SX06 | ZIRCAL-60, 48″ X 48″ X 1/2″ |

| SX07 | ZIRCAL-60, 48″ X 48″ X 3/4″ |

| SX08 | ZIRCAL-60, 48″ X 48″ X 1″ |

| SX09 | ZIRCAL-60, 48″ X 48″ X 1 1/2″ |

| SX10 | ZIRCAL-60, 48″ X 48″ X 2″ |

| SX11 | ZIRCAL-60, 24″ X 48″ X 1/2″ |

| SX12 | ZIRCAL-60, 24″ X 48″ X 3/4″ |

| SX13 | ZIRCAL-60, 24″ X 48″ X 1″ |

| SX14 | ZIRCAL-60, 24″ X 48″ X 1 1/2″ |

| SX15 | ZIRCAL-60, 24″ X 48″ X 1 1/2″ |

| SS01 | ZIRCAL-95, 48″ X 96″ X 1/4″ |

| SS02 | ZIRCAL-95, 48″ X 96″ X 1/2″ |

| SS03 | ZIRCAL-95, 48″ X 96″ X 3/4″ |

| SS04 | ZIRCAL-95, 48″ X 96″ X 1″ |

| SS05 | ZIRCAL-95, 48″ X 96″ X 1 1/4″ |

| SS06 | ZIRCAL-95, 48″ X 96″ X 1 1/2″ |

| SS07 | ZIRCAL-95, 48″ X 96″ X 2″ |

| SS08 | ZIRCAL-95, 48″ X 96″ X 3″ |

| SS10 | ZIRCAL-95, 48″ X 48″ X 1/4″ |

| SS11 | ZIRCAL-95, 48″ X 48″ X 1/2″ |

| SS12 | ZIRCAL-95, 48″ X 48″ X 3/4″ |

| SS13 | ZIRCAL-95, 48″ X 48″ X 1″ |

| SS14 | ZIRCAL-95, 48″ X 48″ X 1 1/4″ |

| SS15 | ZIRCAL-95, 48″ X 48″ X 1 1/2″ |

| SS16 | ZIRCAL-95, 48″ X 48″ X 2″ |

| SS17 | ZIRCAL-95, 48″ X 48″ X 3″ |

| SS20 | ZIRCAL-95, 24″ X 48″ X 1/4″ |

| SS21 | ZIRCAL-95, 24″ X 48″ X 1/2″ |

| SS22 | ZIRCAL-95, 24″ X 48″ X 3/4″ |

| SS23 | ZIRCAL-95, 24″ X 48″ X 1″ |

| SS24 | ZIRCAL-95, 24″ X 48″ X 1 1/4″ |

| SS25 | ZIRCAL-95, 24″ X 48″ X 1 1/2″ |

| SS26 | ZIRCAL-95, 24″ X 48″ X 2″ |

| SS27 | ZIRCAL-95, 24″ X 48″ X 3″ |

| SS80 | ZIRCAL-A, 48″ X 96″ X 1/4″ |

| SS81 | ZIRCAL-A, 48″ X 96″ X 1/2″ |

| SS82 | ZIRCAL-A, 48″ X 96″ X 3/4″ |

| SS83 | ZIRCAL-A, 48″ X 96″ X 1″ |

| SS84 | ZIRCAL-A, 48″ X 96″ X 1 1/4″ |

| SS85 | ZIRCAL-A, 48″ X 96″ X 1 1/2″ |

| SS86 | ZIRCAL-A, 48″ X 96″ X 2″ |

| SS87 | ZIRCAL-A, 48″ X 96″ X 3″ |

| SS88 | ZIRCAL-A, 48″ X 48″ X 1/4″ |

| SS89 | ZIRCAL-A, 48″ X 48″ X 1/2″ |

| SS90 | ZIRCAL-A, 48″ X 48″ X 3/4″ |

| SS91 | ZIRCAL-A, 48″ X 48″ X 1″ |

| SS92 | ZIRCAL-A, 48″ X 48″ X 1 1/4″ |

| SS93 | ZIRCAL-A, 48″ X 48″ X 1 1/2″ |

| SS94 | ZIRCAL-A, 48″ X 48″ X 2″ |

| SS95 | ZIRCAL-A, 48″ X 48″ X 3″ |

ZIRCAL PRODUCTS MEASURING 48″ x 96″ ARE SUBJECT TO A $250 OVER-SIZED PACKAGING AND HANDLING FEE. PRICES ARE SUBJECT TO CHANGE WITHOUT NOTIFICATION AND ARE SUBJECT TO ZIRCAR REFRACTORY COMPOSITES, INC. TERMS AND CONDITIONS. ALL PRICES ARE F.O.B. FLORIDA, NY AND ARE IN U.S. DOLLARS.